We bought two slabs of butcher block from home depot. Two different sizes: a counter top depth slab 6ft long for kitchen counter and then an small island size 4ft slab that we cut for dining table

I used two different products to finish the butcher block:

First, I used cutting board oil and conditioner that I bought from aubachaun- this was used to protect the surface and give the wood some oil. I used these two products while I decided what to buy a more permanent sealer.

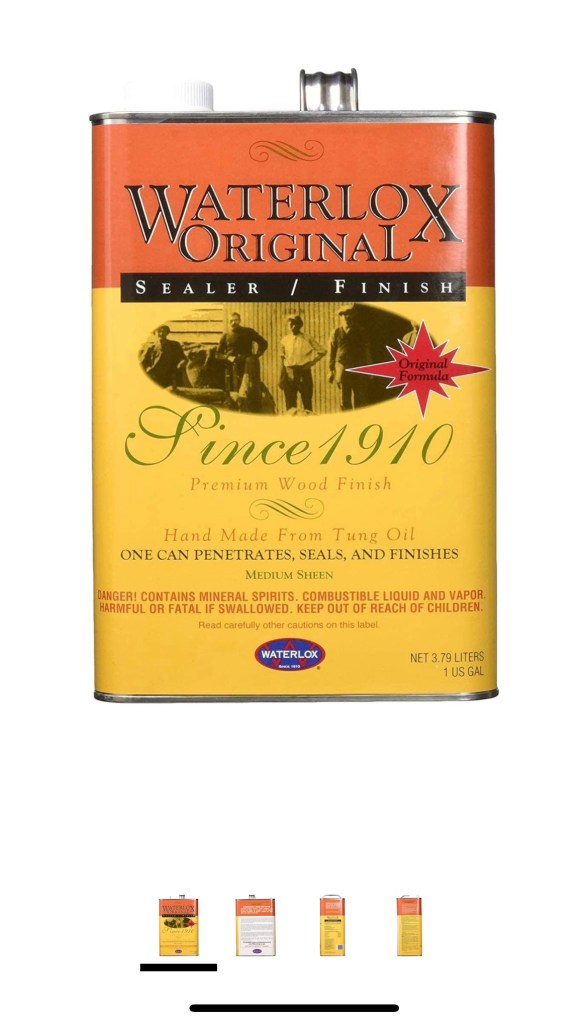

Waterlox—is a durable finish, food safe and advertises that water rings from cups do not show up or leave water ring stains on top of the finish. Can be used in kitchens, bathrooms, or bar projects and is easy to apply and maintain. I would definitely agree with the easy apply

Next, I settled on @waterlox sealer- I decided to use the “medium sheen” option so it has a little sheen and way easier to clean. I was assuming it was going to be a satin finish, but it turns out after 4 coats (water lox required 4 coats for soft wood) – it is semi-gloss sheen for sure!

Steps: (I have this video tutorial on my Instagram page in the IGTV section too!!)

1- Bought butcher block slabs at home depot (counter depth and small island slab)

2- Removed plastic, measured, cut the butcher block to size—both table & countertop—

3- When cutting to size- we used a jig saw, mini circular dewalt saw (my newest tool & obsession)

4- Sanded entire surface and corners- using dewalt circular palm sander – started with 120, 220 – filled all holes or knots with food filler an then did the final run of sanding with 320 grit

5- Cleaned off all sawdust with washcloth and slightly damp paper towels (don’t saturate or wet too much—or you’ll have to wait for it to dry to stain or seal

6- Used @Howards cutting board oil x3 coats

7- Used @Howards wood conditioner x2 coats

8- Waterlox was next—when reading the directions is stated that it is best used when on bare wood- which I didn’t have anymore- I had oiled wood. I did a very light sand with 320 grit to just get a little rough surface for the waterlox to stick to

9- Waterlox recommended 4 coats of the finish for soft wood which is what butcher block is made of.

You have to wait 24 hours in between coats (*just an FYI the finish will go on with bubbles, especially if you use a foam roller- which I did- it will not dry with bubbles like a water based polyurethane willJ )

10- In between coats I took a 320 grit paper and by hand did a very light sand of entire surface- the directions stated this was not necessary, but I did it anyway. (I chose to do it mostly because the surface had oil on it before I did the waterlox- so the more Ican get the layers to stick the better it’ll be/more durable)

11- The ingredients in the waterlox made it so the foam roller did not dry in between all coats, so I was able to continue to use the exact roller for every coat and that was amazing!! J